For thousands of years, the way we build shelter has remained largely unchanged. We cut down trees, we mine stone, we mold bricks, and we stack them one by one. It is a process defined by manual labor, linear timelines, and significant waste. But what if we could press a button and print a house?

This is no longer the stuff of science fiction. 3D Printed Buildings are here, and they are rapidly moving from experimental prototypes to habitable, mortgageable realities. In 2025, we are witnessing the construction industry’s “iPhone moment”—a technological convergence that is fundamentally disrupting the economics, aesthetics, and speed of how we build our world.

From a 100-home community in Texas to the world’s first 3D-printed hotel in the high desert, additive manufacturing is rewriting the rules. It promises a future where homes are built in days, not months; where walls curve as naturally as nature intended; and where the global housing crisis is met with a scalable, digital solution.

In this deep dive, we will explore the mechanics of this revolution, the key players driving it, and why 3D Printed Buildings might just be the most important innovation of the 21st century.

The Mechanics: How Do You “Print” a Building?

To understand the disruption, we must first understand the machine. When we talk about 3D Printed Buildings, we aren’t talking about small plastic desktop printers. We are talking about massive, industrial-grade robots—often gantry systems that look like giant metallic arches or robotic arms on tracks.

The “Ink” and The Nozzle

The process is surprisingly similar to a hot glue gun, but on a monumental scale.

- The Material (The Ink): Instead of plastic, these printers use a proprietary mixture often called “Lavacrete” (by ICON) or similar “biocement” compounds. This material is a high-strength, quick-curing concrete that can hold its shape immediately after being extruded. It needs to be fluid enough to flow but rigid enough not to collapse under the weight of the next layer.

- The Extrusion (The Layering): The printer follows a digital file (a CAD blueprint). It squeezes the concrete out of a nozzle in layers, usually 1 to 2 inches thick. It goes back and forth, tracing the walls of the home.

- The Result: You get a wall with a distinctive “ribbed” texture. These walls are hollow in the middle, allowing for insulation, electrical, and plumbing to be run inside before being filled for structural solidity.

This process is continuous. A printer can run 24 hours a day, pausing only for material refills or safety checks. It doesn’t get tired, it doesn’t get injured, and it doesn’t take lunch breaks.

The Disruption: Speed, Cost, and Freedom

Why go through the trouble of inventing a robot to do a bricklayer’s job? Because 3D Printed Buildings offer three critical advantages that traditional construction simply cannot match.

1. Radical Speed

Time is the most expensive commodity in construction. A traditional framing crew might take weeks to erect the walls of a house. A 3D printer can do the same work in 24 to 48 hours of print time.

- Case in Point: In 2024, charitable organizations used 3D printing to rebuild disaster-stricken zones in days, providing permanent shelter for families who lost everything. The speed allows for rapid deployment in crises.

2. Cost and Labor Efficiency

The construction industry is facing a massive global labor shortage. Fewer young people are entering the trades. 3D Printed Buildings bridge this gap. You don’t need a crew of 10 framers; you need one machine operator and a small support team. Additionally, the precision of the printer means zero waste. In traditional wood framing, tons of lumber are cut off and thrown into dumpsters. The printer only uses exactly the material needed for the wall.

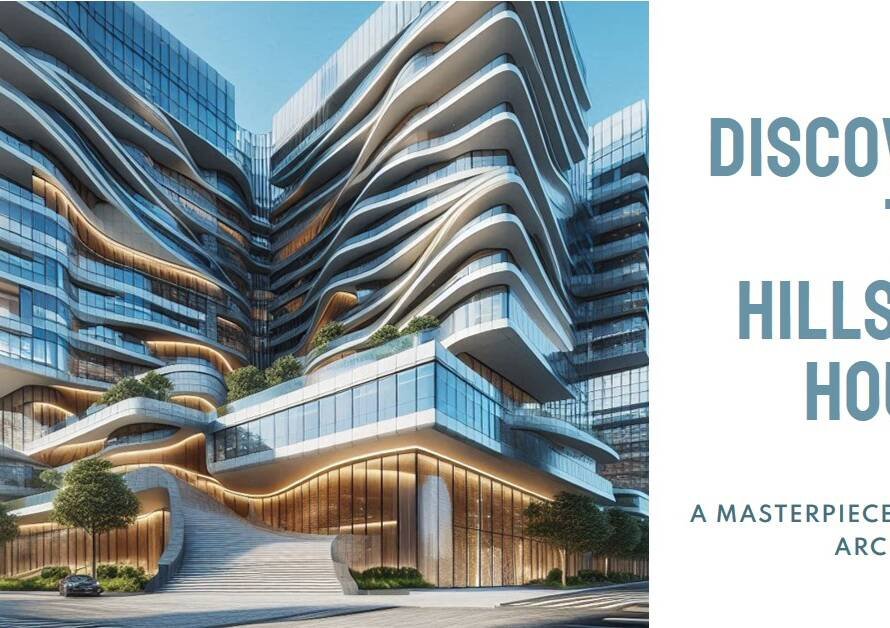

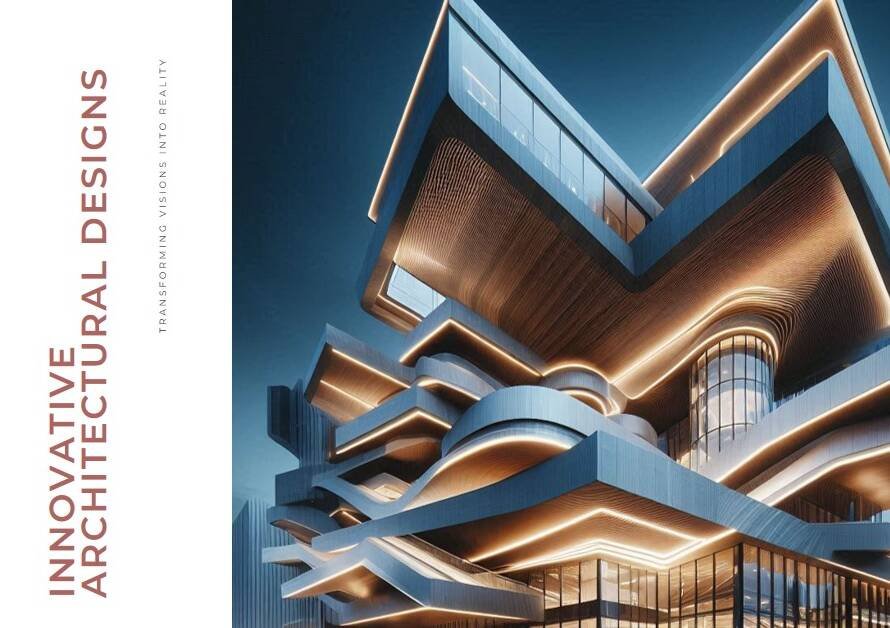

3. Design Freedom: The End of the Box

This is perhaps the most exciting disruption. In traditional building, straight lines are cheap, and curves are expensive. Every time you want a curved wall, you need custom formwork and skilled artisans. With 3D Printed Buildings, curves cost the same as straight lines. The printer doesn’t care if it moves in a circle or a square. This has unleashed a new wave of “organic architecture.” Architects are designing homes with sweeping curves, rounded corners, and biological shapes that feel more like they grew out of the ground than were assembled upon it.

Real-World Proof: Wolf Ranch and El Cosmico

If you think this is still experimental, look at Texas. The state has become the global capital of 3D Printed Buildings.

Wolf Ranch: The Mass Adoption

Located in Georgetown, Texas, Wolf Ranch is a partnership between ICON (the tech company) and Lennar (one of America’s largest homebuilders). It is a community of 100 3D-printed homes.

- These aren’t tiny prototype huts; they are 3-4 bedroom family homes.

- They sold out almost as fast as they were printed.

- Residents report that the concrete walls provide near-perfect soundproofing and exceptional thermal insulation, keeping electricity bills low during brutal Texas summers. Wolf Ranch proves that 3D Printed Buildings are ready for the mass market. They are insurable, code-compliant, and desirable.

El Cosmico: The Viral Aesthetic

While Wolf Ranch proves the utility, El Cosmico in Marfa, Texas, proves the beauty. Expanding on an existing bohemian hotel, this project (currently under construction in 2025) is the world’s first 3D Printed Hotel. Designed by the famous architecture firm BIG (Bjarke Ingels Group), the structures are a series of intersecting domes and vaults. They are colored to match the high desert sand. It is a project that would be astronomically expensive to build with wood or brick, but with 3D printing, it is feasible. It stands as a testament to the “design freedom” promised by the technology.

The Environmental Impact: Concrete vs. The Climate

There is an elephant in the room: Concrete. Traditional cement production is responsible for about 8% of global CO2 emissions. So, isn’t printing with concrete bad for the planet?

It’s a valid concern, but the industry is innovating rapidly to solve it.

- Material Reduction: Because 3D Printed Buildings use topology optimization (putting material only where the physics says it’s needed), they use up to 50% less material than a solid concrete block wall.

- Green Cement: Companies are developing “lavacrete” alternatives that use fly ash, slag, and even local soil to replace Portland cement.

- Local Sourcing: In the future, the goal is to print with the dirt right under our feet. This eliminates the carbon footprint of trucking materials to the site. Imagine a printer arriving at a site, digging up the earth, mixing it with a binding agent, and printing a home.

The Future: From Suburbs to Space

The disruption of 3D Printed Buildings on Earth is just the rehearsal. The ultimate destination for this technology is the stars. NASA has partnered with companies like ICON for “Project Olympus”—a program to develop construction systems for the Moon and Mars. Why? Because you cannot fly Home Depot to Mars. To live on another planet, we must build with the materials we find there (Regolith). 3D Printed Buildings are the only viable solution for extraterrestrial colonization. The technology perfecting the $400,000 home in Austin is the same technology that will build the first habitat in the Jezero Crater.

But back on Earth, the next 5 years (2025-2030) will see:

- Multi-Story Printing: We are already seeing prototypes of 2 and 3-story printed buildings (like Project Milestone in the Netherlands).

- Printed Infrastructure: Bridges, wind turbine bases, and sea walls printed on-site.

- Hyper-Local Customization: You will download a house design, customize it to your lot’s dimensions, and hit “print.”

Conclusion

We are living through a pivotal moment in history. Just as the elevator made the skyscraper possible, 3D Printed Buildings are making the “responsive home” possible.

This technology disrupts the construction industry by turning it from a manual, chaotic process into a precise, digital manufacturing process. It offers a path to affordable housing, sustainable materials, and architectural beauty that was previously reserved for the ultra-wealthy.

The walls of the future will not be stacked; they will be extruded. And they will be stronger, smarter, and more beautiful than anything we have built before.

Are 3D printed buildings safe?

Yes. 3D Printed Buildings are built to meet or exceed local building codes. The reinforced concrete structures are incredibly durable and are often more resistant to extreme weather, fire, and termites than traditional wood-framed homes.

Is it cheaper to buy a 3D printed house?

Currently, the cost is comparable to traditional construction, but slightly lower (approx. 10-15% savings on the wall system). However, as the technology scales and becomes more common, experts predict costs could drop by 30-50% due to reduced labor and speed.

How long do 3D printed houses last?

They are built from concrete, one of the most durable materials on Earth. A well-maintained 3D Printed Building is expected to last 50 to 100 years or more, similar to traditional masonry buildings.

Can you print a roof?

Generally, no. Most current 3D Printed Buildings print the walls, but the roof, windows, and doors are installed using traditional methods. However, new techniques are being developed to print domed roofs that are self-supporting

What happens if the printer breaks down in the middle of a print?

This is a common challenge. Printers have “cold joints” if they stop for too long (the previous layer dries out). Manufacturers have developed sophisticated software to handle “stop-start” procedures, ensuring that when the printer restarts, it bonds perfectly with the previous layer.