Table of Contents

Walk onto a major construction site in 2025, and the soundscape has changed. Amidst the familiar roar of diesel engines and the shouting of foremen, there is a new sound: the electric whir of servos and the hydraulic hiss of automation. We are witnessing the dawn of Construction Robotics, a technological revolution that is transforming the job site from a place of manual labor into a theater of automated precision.

For decades, the construction industry was the land that time forgot. While manufacturing embraced the assembly line and agriculture adopted automated harvesters, construction remained stubbornly analog. It was dangerous, dirty, and dependent on declining pools of skilled labor. But the tipping point has arrived. Facing a global shortage of workers and a desperate need for housing, the industry is turning to machines not just to assist, but to build.

Construction Robotics is no longer a futuristic novelty reserved for tech expos. It is digging foundations in Dubai, laying bricks in Australia, and tying rebar in New York. In this extensive guide, we will explore the robots roaming our job sites today, the economic forces driving their adoption, and the ethical questions they raise about the future of human work.

The Driving Force: Why Robots? Why Now?

To understand the sudden explosion of Construction Robotics, we have to look at the numbers. The construction industry is facing a perfect storm.

- The Labor Crisis: The “Silver Tsunami” is real. Older tradespeople are retiring, and younger generations are choosing laptops over jackhammers. In the US alone, the construction industry is short over half a million workers. Robots fill this gap—they don’t retire, and they don’t get tired.

- Safety Mandates: Construction kills. It is consistently one of the most dangerous professions globally. By assigning high-risk tasks—like working at heights or in toxic environments—to robots, companies can drastically reduce injuries and insurance premiums.

- Productivity Stagnation: While manufacturing productivity has skyrocketed by 760% since the 1940s, construction productivity has barely budged (some studies say it has actually declined). Construction Robotics is the lever to break this stagnation.

The New Crew: Types of Construction Robots

The term “robot” is broad. On the modern job site, Construction Robotics manifests in four distinct categories, each solving a specific problem.

1. The Heavy Lifters: Automated Bricklayers and Masons

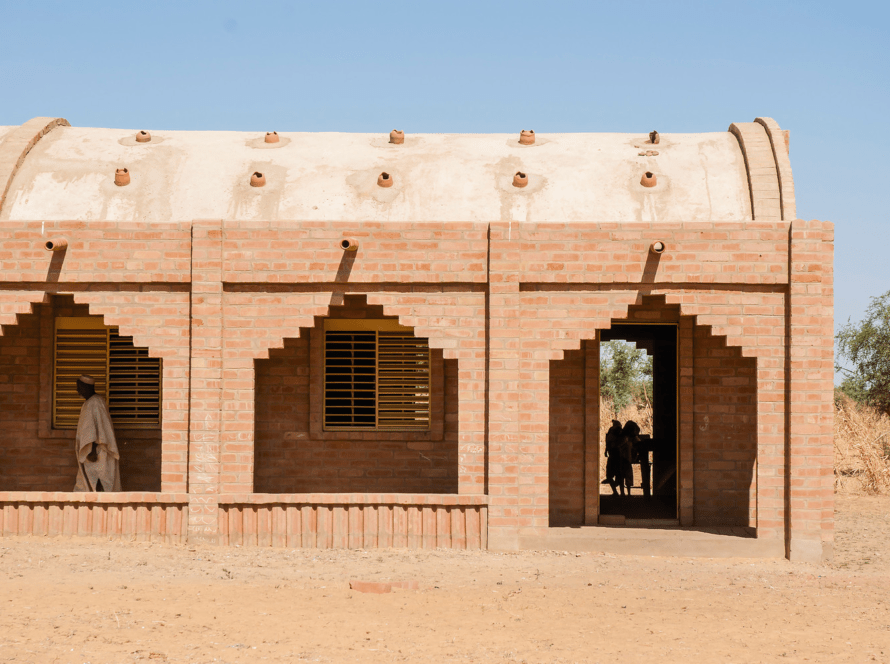

Laying brick is back-breaking, repetitive work that requires high skill. It is the perfect candidate for automation.

- Hadrian X (FBR): The celebrity of the construction world. This truck-mounted robot can lay 1,000 blocks per hour—about the output of two days’ work for a human mason—with sub-millimeter precision. It uses a 30-meter boom to reach across a site, guided by a CAD design, placing blocks glued together with a special adhesive rather than mortar.

- SAM100 (Construction Robotics): The Semi-Automated Mason. Unlike Hadrian X, SAM works with a human mason. The robot lifts, butters, and places the brick, while the human scrapes the excess mortar and handles the complex corners. It’s a “cobot” (collaborative robot) that increases a mason’s productivity by 300-500%.

2. The Inspectors: Drones and Quadrupedal Bots

Before you can build, you must measure. And while you build, you must inspect.

- Spot (Boston Dynamics): You have seen the yellow dog dancing on YouTube. On a job site, Spot is a serious worker. Equipped with 360-degree cameras and LiDAR scanners, Spot walks the site autonomously every night. It captures data to create a “Digital Twin” of the progress, flagging if a pipe is installed two inches to the left of the plan. This prevents expensive rework.

- Drones (UAVs): Aerial drones have moved from photography to photogrammetry. They map entire sites in minutes, calculating stockpile volumes (how much gravel do we have?) and checking site safety perimeters.

3. The Task Masters: Rebar and Drywall Robots

Some jobs are just tedious. Tying rebar (twisting wire to hold steel bars together) causes repetitive strain injuries (RSI) in thousands of workers every year.

- TyBot: This autonomous robot glides along the rebar grid of a bridge deck. It uses computer vision to identify intersections and ties them faster than a human crew, working day and night, rain or shine.

- Canvas: A drywall finishing robot. Drywall finishing (mudding and sanding) is dusty and physically demanding. Canvas uses a robotic arm on a mobile base to spray and sand drywall to a “Level 5” finish (perfect smoothness) every time, sucking up the dust as it goes.

4. The Augmenters: Exoskeletons

Not all Construction Robotics replace humans; some make humans super-powered.

- Passive Exoskeletons: Suits like the EksoBionics vest use springs and counterweights (no motors) to make lifting a 40lb tool feel like lifting 5lbs. They reduce fatigue and prevent back injuries for overhead work.

- Active Exoskeletons: Powered suits (like the Sarcos Guardian XO) that allow a single worker to lift 200lbs as if it were a feather. These are transforming logistics and material handling on site.

The Tech Stack: How Do They See?

A robot in a car factory has it easy. It is bolted to the floor, and the car comes to it in the exact same position every time. A construction site is chaos—mud, rain, moving trucks, and shifting debris. How does Construction Robotics cope?

LiDAR and SLAM

Robots use LiDAR (Light Detection and Ranging) to shoot millions of laser pulses per second, creating a 3D map of the world. They use SLAM (Simultaneous Localization and Mapping) to figure out “Where am I?” and “What is around me?” in real-time. This allows a robot to navigate around a pile of lumber that wasn’t there yesterday.

BIM Integration

Building Information Modeling (BIM) is the robot’s brain. The robot doesn’t “guess” where the wall goes; it downloads the exact coordinates from the BIM file. This closes the gap between the architect’s vision and the built reality. If the architect changes a wall in the digital model, the robot on-site knows about it instantly.

The Economic Impact: Cost vs. Value

The elephant in the room is cost. Construction Robotics are expensive. A single unit can cost upwards of $500,000. For small contractors, this is a non-starter.

However, the economic model is shifting to RaaS (Robots as a Service). Instead of buying a TyBot, a contractor rents it for the duration of the bridge pour. They pay by the tie, or by the square foot. This lowers the barrier to entry and shifts the cost from CapEx (Capital Expenditure) to OpEx (Operational Expenditure).

The ROI Calculation:

- Speed: A robot can work 24/7. Finishing a project 2 months early saves millions in loan interest and overhead.

- Quality: A robot doesn’t have a “bad day.” It doesn’t install a window upside down. Reducing rework (which accounts for ~5% of total construction costs) pays for the robot itself.

- Safety: One fewer back injury claim can save a company tens of thousands of dollars.

Challenges: It’s Not All Smooth Concrete

Despite the hype, Construction Robotics faces significant hurdles.

- Connectivity: Robots need high-speed data to talk to the cloud. Many job sites are in remote areas with poor 4G/5G coverage.

- Battery Life: A heavy-duty robot needs massive power. Running extension cords across a site is dangerous, and batteries often don’t last a full shift.

- Union Resistance: While unions are generally supportive of safety robots (like drones), there is natural friction regarding robots that replace skilled labor (like bricklayers). The industry must navigate this transition by emphasizing retraining workers to become “Robot Operators” rather than replacing them.

The Future: Swarms and AI Generalists

What does 2030 look like?

We are moving toward Swarm Robotics. Instead of one giant crane, imagine 50 small drones working in concert to lift a beam. If one drone fails, the others adjust. This mimics nature (ants/bees) and creates a system with zero single points of failure.

We will also see the rise of AI Generalists. Currently, robots are specialists (Spot walks, Hadrian lays bricks). The “Holy Grail” is a humanoid robot (like Tesla’s Optimus or Boston Dynamics’ Atlas) that can pick up a hammer, then a drill, then drive a truck. While we are years away from this being commercially viable on a job site, the R&D is accelerating.

Conclusion

Construction Robotics is not coming; it is here. It is the inevitable answer to a world that demands more infrastructure, faster, and with fewer available hands to build it.

For the construction worker, the future is not about being replaced; it is about being upgraded. The worker of tomorrow will not be valued for their muscle power, but for their ability to manage a fleet of machines. They will trade their toolbelt for a tablet, and their back pain for a battery charger.

The automated job site is a safer, cleaner, and more efficient environment. As these technologies mature, we will see buildings rise at speeds previously thought impossible, rewriting the skyline of human potential.

Frequently Asked Questions (FAQ)

Will robots replace construction workers?

Robots will replace tasks, not entire jobs. Dangerous, repetitive, and heavy tasks will be automated. However, human judgment, complex problem-solving, and adaptability are still superior. The role of the worker will shift to “Robot Operator” and “Site Manager.”

How much does a bricklaying robot cost?

Large systems like the Hadrian X are typically not sold but leased under a “Wall as a Service” model. Smaller collaborative robots like SAM100 can cost around $500,000, though prices are dropping as adoption increases.

Can robots work in the rain?

Most industrial Construction Robotics are rated IP65 or higher, meaning they can handle dust and water jets. However, extreme weather (high winds for cranes/drones, freezing temps for batteries) still poses a challenge.

Do construction robots use AI?

Yes. They use “Computer Vision” (a form of AI) to see and understand the environment. They also use Machine Learning to improve over time—for example, a robot learning the best way to grip a slippery pipe after several attempts.

What is the biggest barrier to adoption?

Culture. The construction industry is traditional and risk-averse. Convincing site superintendents to trust a robot over a crew they have known for 20 years is the hardest part of the implementation.