Table of Contents

The construction industry has historically been one of the slowest sectors to digitize. For decades, the image of a construction site has been defined by mud, paper blueprints, and superintendents walking miles every day to visually inspect progress. But look up today, and you will likely see a different story buzzing overhead. Construction Drones—technically known as Unmanned Aerial Vehicles (UAVs)—have fundamentally altered the perspective of the job site.

They are no longer just toys for capturing marketing photos; they are industrial data-gathering tools that are boosting site efficiency by orders of magnitude. What used to take a team of surveyors three weeks to map can now be done by a single Construction Drone in 20 minutes. What used to require a dangerous climb up a scaffolding tower to inspect can now be viewed in 4K resolution from the safety of the ground.

In this extensive guide, we will move beyond the hype and explore the granular mechanics of how Construction Drones are revolutionizing the industry. We will dissect the difference between photogrammetry and LiDAR, compare the hardware, analyze the legal landscape, and demonstrate exactly how this technology translates into millions of dollars saved.

The Evolution: From Clipboards to Quadcopters

To understand the impact of Construction Drones, we have to look at the baseline of the industry. Before drones, site intelligence was gathered manually. If a project manager wanted to know how much earth had been moved in the last week, they had to rely on truck counts (which are notoriously inaccurate) or schedule a ground survey team. Ground surveying is precise, but it is slow, expensive, and disruptive to site operations.

Construction Drones introduced the concept of “Continuous Aerial Intelligence.” Instead of a snapshot of the site once a month, managers can now have a high-resolution, 3D map of the site every single morning. This shift from “periodic data” to “continuous data” allows for real-time decision-making that was previously impossible.

The Three Pillars of Drone Efficiency

- Speed: Drones capture data up to 20x faster than traditional ground-based methods.

- Access: Drones can reach areas that are unsafe or impossible for humans, such as steep embankments, fragile roofs, or active blast zones.

- Data Density: A human surveyor captures points on a 10-foot grid. A drone captures millions of points, creating a comprehensive digital surface model where no detail is missed.

The Technology: Photogrammetry vs. LiDAR

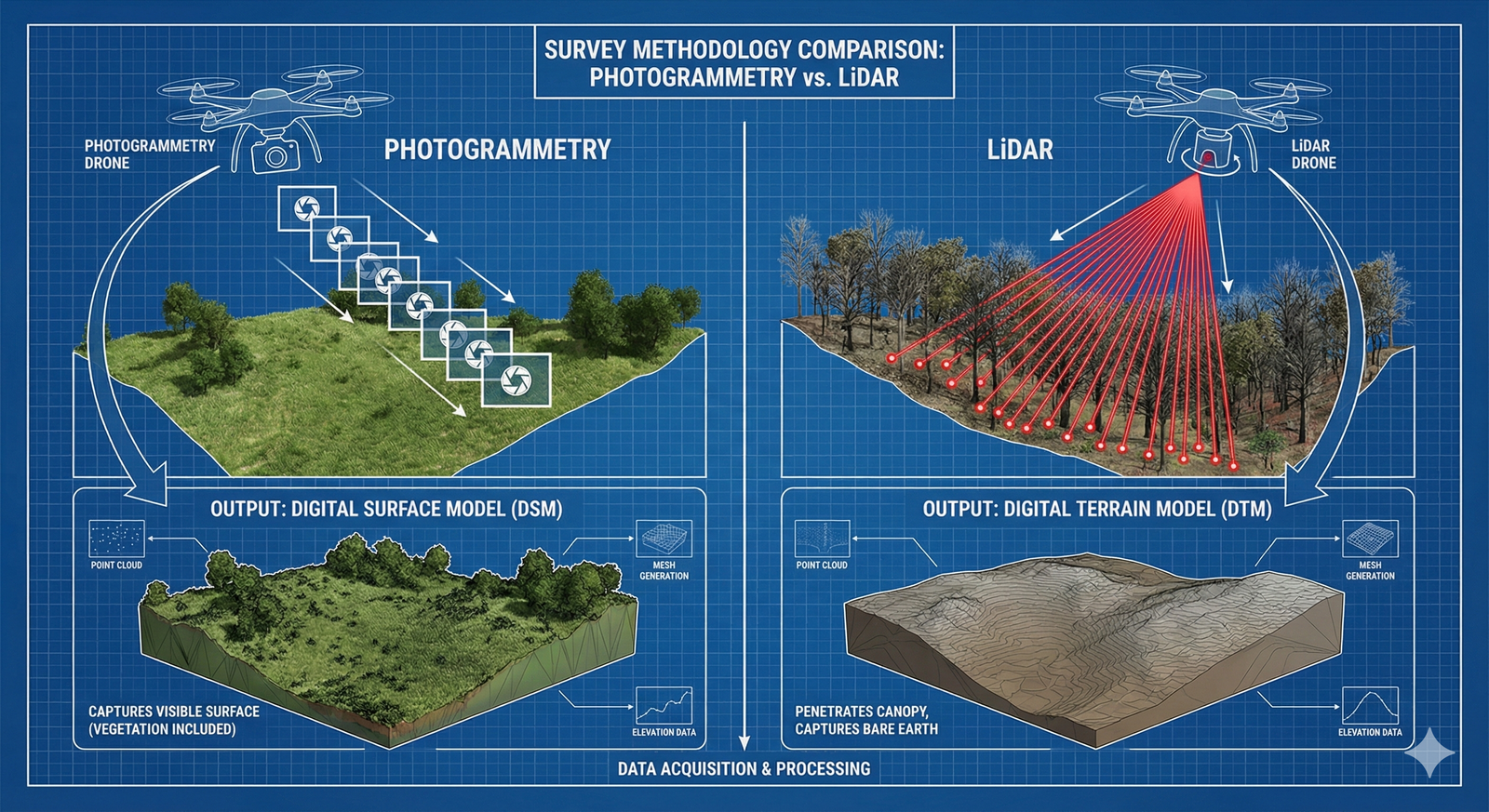

When we talk about Construction Drones, we aren’t just talking about the flying machine; we are talking about the sensor payload. There are two primary technologies used to map sites, and understanding the difference is critical for adoption.

1. Photogrammetry (The Visual Mapper)

Photogrammetry is the science of making measurements from photographs. A drone flies a grid pattern over the site, taking hundreds of overlapping photos (usually with 70-80% overlap). Software then stitches these photos together by identifying common “tie points” (like a rock or a painted line) that appear in multiple images.

- Pros: Cheaper hardware (standard high-res cameras), excellent for visual inspections, produces photo-realistic 3D models.

- Cons: Struggles with dense vegetation (it only sees the top of the trees, not the ground).

2. LiDAR (The Laser Scanner)

LiDAR (Light Detection and Ranging) is the heavy hitter. The drone shoots laser pulses toward the ground—up to hundreds of thousands of pulses per second—and measures how long it takes for the light to bounce back.

- Pros: Can “penetrate” vegetation to map the true ground level (essential for earthworks in wooded areas), extremely accurate, works in low light.

- Cons: Expensive sensors (often $20k+), produces point clouds that are harder to interpret visually than photos.

Core Applications: Where Drones Make Money

Construction Drones are boosting efficiency across the entire lifecycle of a project, from the initial bid to the final handover.

1. Topographic Surveying and Pre-Construction

Before a shovel hits the ground, you need to know the land. Traditional topographic surveys are time-consuming. A drone can fly a 100-acre site in less than an hour, producing a map with 1-2cm accuracy (when using RTK/PPK GPS systems). This allows estimators to bid more accurately. If the drone data shows that the site is 2 feet lower than the outdated municipal maps suggested, the contractor knows they need to import fill dirt, adjusting their bid by thousands of dollars and preventing a budget crisis later.

2. Volumetric Measurements (Stockpile Analysis)

Tracking inventory of gravel, sand, and aggregate is a headache. Traditionally, a surveyor climbs the pile (a safety risk) and estimates the volume. Construction Drones fly over the pile, create a 3D mesh, and the software calculates the volume instantly with 99% accuracy. Companies like Granite Construction have reported that drone stockpile measurements are 98% faster and vastly safer than manual methods.

3. Progress Tracking and “The Single Source of Truth”

Disputes are common in construction. “The concrete was poured on Tuesday,” says the sub-contractor. “No, it wasn’t,” says the general contractor. With daily or weekly drone flights, there is an indisputable visual record. You can slide a time bar back and see exactly what the site looked like on Tuesday. This “Single Source of Truth” reduces litigation and keeps meetings focused on facts, not arguments.

4. Thermal Inspection

Drones equipped with thermal cameras are used to inspect building envelopes for heat leaks. On large commercial roofs, a thermal drone can identify wet insulation under the membrane (which retains heat longer than dry insulation) without a person having to cut destructive test cores.

Hardware Guide: Choosing the Right Bird

Not all Construction Drones are created equal. The choice depends on the size of the site and the data needed.

Multi-Rotor Drones (Quadcopters/Hexacopters)

- Examples: DJI Mavic 3 Enterprise, DJI Matrice 350 RTK, Skydio X10.

- Best For: Vertical inspections, smaller sites (under 100 acres), hovering, close-up photography.

- The Workhorse: Multi-rotors are the most common because they are easy to fly and can take off vertically from a cluttered job site.

Fixed-Wing Drones (VTOL)

- Examples: WingtraOne, eBee X.

- Best For: Massive sites (highway corridors, pipelines, 500+ acres).

- The Marathon Runner: These drones fly like an airplane. They are more efficient and can cover huge distances on a single battery, but they generally cannot hover or inspect vertical facades effectively.

Drone-in-a-Box (Autonomous Docking)

- The Future: This is a drone that lives on the job site in a weatherproof box. At a scheduled time, the box opens, the drone launches, flies the mission, lands, and charges itself—all without a pilot on site. This is the holy grail of automation, currently being pioneered by companies like Percepto and Skydio.

Software Ecosystem: Turning Images into Insights

The drone is just the data capture tool; the real value lies in the software. Construction Drones feed into a rich ecosystem of processing platforms.

- DroneDeploy: The market leader for user-friendly processing. It creates 2D orthomosaics (giant stitched maps) and 3D models in the cloud.

- Pix4D: A more technical, desktop-based solution favored by professional surveyors for its granular control over accuracy and projections.

- Propeller: Famous for its “AeroPoints” (smart ground control points) that make georeferencing incredibly simple for non-surveyors.

These platforms integrate directly with CAD and BIM software (Autodesk Revit, Civil 3D, Procore). This integration is crucial. You can overlay the drone map (reality) on top of the design drawings (plan) to catch deviations instantly.

Safety and Regulation: The Rules of the Sky

You cannot just buy a drone and start flying over a construction site. There are strict legal frameworks, particularly in the US (FAA) and Europe (EASA).

FAA Part 107 (United States)

In the US, any drone flight for commercial purposes requires a pilot with a Part 107 Remote Pilot Certificate. This involves passing an aeronautical knowledge test covering weather, airspace classifications, and radio communications.

Critical Restrictions

- Visual Line of Sight (VLOS): You must be able to see the drone with your naked eye at all times. (Exceptions, or waivers, are required for Beyond Visual Line of Sight – BVLOS).

- Flying Over People: Strictly regulated. You generally cannot fly over people unless they are part of the operation or under a covered structure. This is a major consideration on active job sites; flights are often scheduled during lunch breaks or shift changes to avoid flying over workers.

- Airspace Authorization: Many construction sites are in cities near airports (controlled airspace). Pilots must use systems like LAANC (Low Altitude Authorization and Notification Capability) to get instant digital permission to fly near airports.

ROI Case Study: The Hospital Project

Let’s look at a hypothetical but realistic scenario to illustrate ROI.

Project: A $100M Hospital Complex. Challenge: The facade installation is behind schedule, and the owner is demanding updates. Traditional Method: Two superintendents spend 3 days walking the perimeter, taking photos with phones, and manually marking up PDF drawings. Cost: $3,000 in labor. Result: Fragmented data, photos stored in random folders. Drone Method: A pilot flies a 30-minute automated orbit mission. The data is processed overnight. Cost: $200 (internal cost). Result: A complete 3D digital twin of the exterior. The team spots that the window flashings on the 4th floor are missing before the scaffolding is taken down. Savings: Catching that error saved $50,000 in rework (re-erecting scaffolding later). The ROI on the drone program for that single flight is astronomical.

Future Trends: AI and Swarms

As we look toward 2030, Construction Drones are getting smarter.

- Real-Time AI Analysis: Currently, data is processed after the flight. Soon, drones will have onboard AI chips that identify safety hazards (e.g., “Worker not wearing hard hat” or “Guardrail missing”) while they are flying and alert the safety officer instantly.

- Swarm Intelligence: Instead of one pilot flying one drone, a single operator will oversee a swarm of 5 drones working in concert—one mapping, one inspecting thermal, and one delivering small tools to the roof.

Conclusion

Construction Drones have graduated. They have passed the “early adopter” phase and are now a standard requirement for competitive general contractors. The question is no longer “Should we use drones?” but “How deeply can we integrate them?”

By adopting aerial intelligence, construction firms are breaking free from the limitations of the ground. They are building faster because they have better data. They are building safer because they keep humans out of harm’s way. And they are building cheaper because they catch mistakes before they become concrete.

In an industry with razor-thin margins, the view from above is often the difference between profit and loss.

Frequently Asked Questions (FAQ)

How accurate are construction drones?

With standard GPS, they are accurate to within 1-2 meters. However, using RTK (Real-Time Kinematic) or PPK (Post-Processed Kinematic) technology and Ground Control Points (GCPs), Construction Drones can achieve survey-grade accuracy of 1-2 centimeters.

Can drones fly in the rain?

Most consumer drones cannot. However, enterprise Construction Drones like the DJI Matrice 300/350 series have IP ratings (like IP45 or IP55) that allow them to fly in light to moderate rain. High winds (above 25 mph) are generally the bigger limiting factor than rain.

How much does a construction drone cost?

A starter setup (like a DJI Mavic 3 Enterprise) costs around $4,000 – $6,000. A high-end setup with LiDAR and RTK base stations (like a Matrice 350) can cost upwards of $30,000 – $50,000.

Do I need insurance for a drone?

Legally, it depends on the country, but practically, yes. Liability insurance is essential. If a drone falls out of the sky and hits a car or a person, the liability is massive. Most reputable contractors carry at least $1M-$5M in aviation liability coverage.

Is drone data compatible with BIM software?

Yes. Drone software exports common file formats like .LAS (point clouds), .OBJ (3D models), and .TIFF (orthomosaics). These can be imported directly into Autodesk Revit, Civil 3D, Navisworks, and Procore.